Core Technology

—

Solution

—

Customer Case

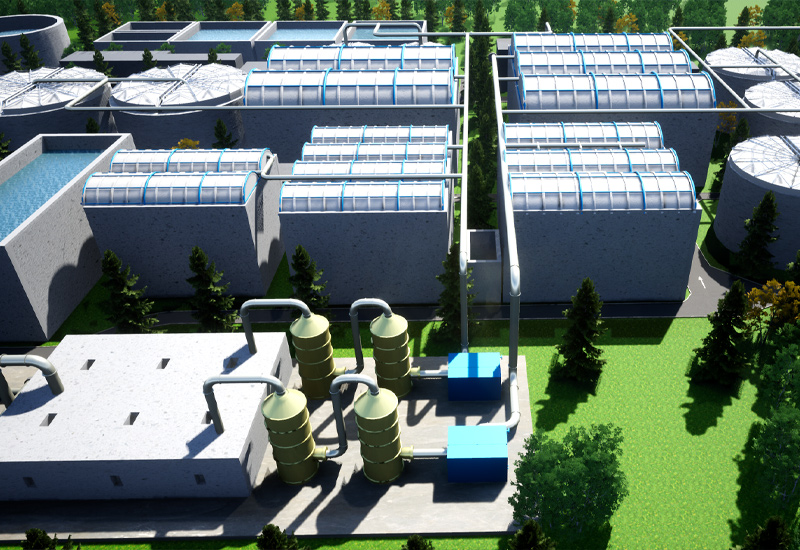

INDUSTRIAL APPLICATION

—

Recent Achievements

—

|

Industry |

Customer Name |

Project Name |

Area |

Workmanship |

Project Scale |

|

sewage-treatment plant |

Fujian Haihuan Pengyao Resource Development Co., Ltd |

Upgrading of deodorization system for sludge disposal project in Yangli sewage treatment plant |

Fujian |

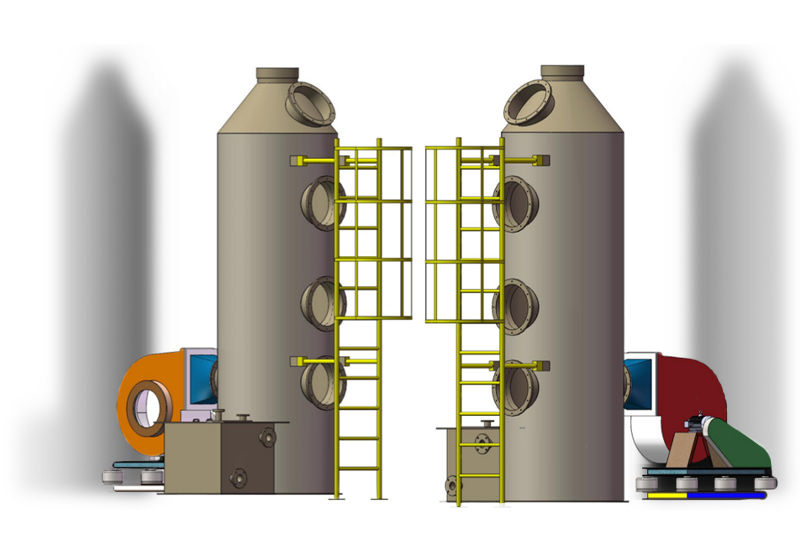

bio-trickling filter |

400000m3/h |

|

sewage-treatment plant |

Fujian Shentou Strait Environmental Protection Technology Co., Ltd |

Fuzhou hazardous waste comprehensive disposal waste gas treatment system complete set of equipment |

Fujian |

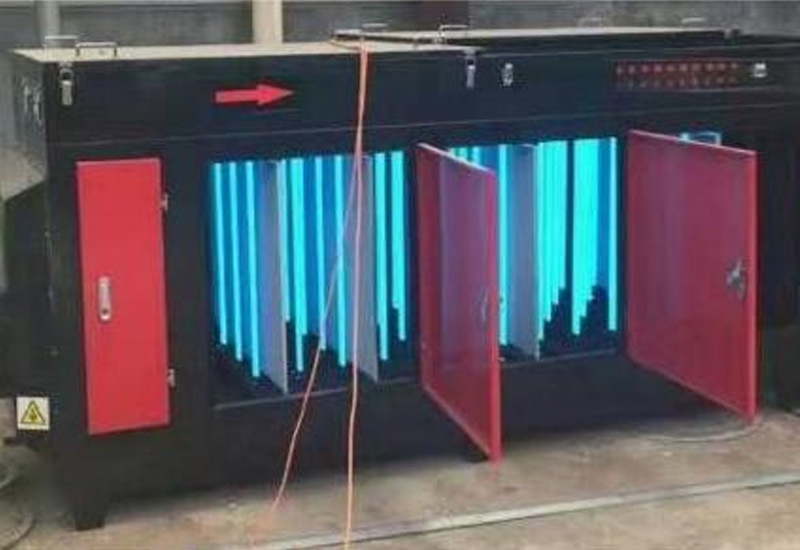

Washing+photocatalytic oxidation+activated carbon adsorption |

50000m³/h |

|

kitchen waste |

Changsha Zoomlion Environmental Industry Co., Ltd |

Procurement of Deodorization System for Changde Kitchen Project |

Hunan |

Acid alkali washing+biofilter+low-temperature plasma |

165000m3/h |

|

kitchen waste |

Changsha Zoomlion Environmental Industry Co., Ltd |

Procurement of Deodorization System for Yichun Kitchen and Kitchen Project |

Jiangxi |

Acid alkali washing+biofilter+low-temperature plasma |

175000m3/h |

|

kitchen waste |

Changsha Zoomlion Environmental Industry Co., Ltd |

Procurement of deodorization system for Huai'an kitchen project |

Jiangsu |

Acid alkali washing+biofilter+low-temperature plasma |

45000m3/h |

|

waste transfer station |

Changsha Zoomlion Environmental Industry Co., Ltd |

Hangzhou Chengxi Deodorization Project |

Zhejiang |

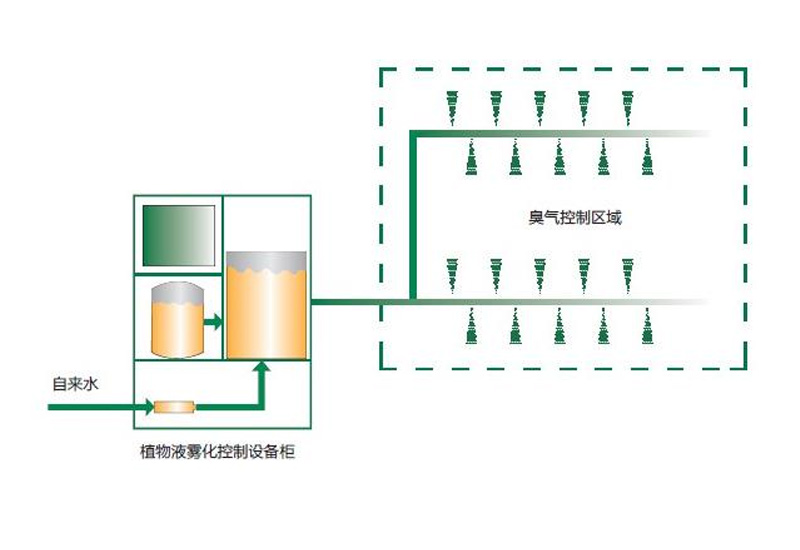

Chemical washing+plant liquid spraying+activated carbon |

280000m³/h |

|

waste transfer station |

Changsha Zoomlion Environmental Industry Co., Ltd |

Guangxi Nanning Deodorization Project |

Guangxi |

Chemical washing+plant liquid spraying+biofilter |

325000m³/h |

|

waste transfer station |

Changsha Zoomlion Environmental Industry Co., Ltd |

Guizhou Guiyang Deodorization Project |

Guizhou |

Chemical washing+plant solution spraying+ion fresh air |

1100000m³/h |

|

waste transfer station |

Changsha Zoomlion Environmental Industry Co., Ltd |

Hunan Linli Deodorization Project |

Hunan |

Chemical washing+plant solution spraying+ion fresh air |

160000m³/h |

|

waste transfer station |

Changsha Zoomlion Environmental Industry Co., Ltd |

Shanxi Taiyuan Deodorization Project |

Shanxi |

Chemical washing+plant solution spraying+ion fresh air |

160000m³/h |

Language

Language